Επισημαίνω:

Συλλέκτης σκόνης με υδραστική ταινία

, Προσαρμόσιμο συλλέκτη σκόνης με φιλμ νερού

Δυναμικό επεξεργασίας: |

1-20 τόνους/ώρα |

Αποδοτικότητα απομάκρυνσης σκόνης: |

≥99% |

Όγκος αέρα: |

2.000~50.000m³/ώρα (Πολλαπλοί πύργοι μπορούν να συνδεθούν παράλληλα) |

Αποδοτικότητα απομάκρυνσης σκόνης: |

≥95% (μέγεθος σωματιδίων>5μm) |

Εφαρμογές: |

Παραγωγή λιπασμάτων, κόκκωση, γραμμές συσκευασίας |

Αντίσταση εξοπλισμού: |

800~1.200Pa |

Όνομα προϊόντος: |

Συλλέκτης σκόνης με υδραστική ταινία |

Επισκόπηση του προϊόντος

Συλλέκτης σκόνης με υδατική ταινίαείναι εξοπλισμός απομάκρυνσης υγρής σκόνης που χρησιμοποιεί ένα υδατικό κάλυμμα (υδατικό κάλυμμα) ή ένα σύστημα ψεκασμού για τη συλλογή, την προσρόφηση και την απομάκρυνση σκόνης, καπνού και επιβλαβών αερίων στα βιομηχανικά απόβλητα.Η βασική αρχή του είναι η συλλογή ρύπων από σταγόνες νερού ή υδατικά φιλμ μέσω της επαφής αερίου με υγρό, επιτυγχάνοντας έτσι τον σκοπό καθαρισμού των αποβλήτων αερίου.

Χαρακτηριστικά

1Ειδικεύεται στην επεξεργασία της NPK συνδυασμένης σκόνης λιπασμάτων, των αποβλήτων από τη ζύμωση οργανικών λιπασμάτων, της αμμωνίας (NH3) και άλλων ρύπων που σχετίζονται με την παραγωγή λιπασμάτων

2Η αποτελεσματικότητα απομάκρυνσης σκόνης 5μm και άνω μπορεί να φθάσει το 90% ~ 98%.

3. Χαμηλό κόστος και υψηλή απόδοση

Είναι πιο ανθεκτικό στην υγρασία από την απομάκρυνση σκόνης από σακούλες (λύει το πρόβλημα της υδροσκοπικότητας των λιπασμάτων), εξοικονομεί το 40% της επένδυσης σε σύγκριση με την ηλεκτροστατική απομάκρυνση σκόνης και είναι εύκολο στη συντήρηση.

4. Περιβαλλοντικά συμμορφούμενες, που πληρούν τα πρότυπα εκπομπών ατμοσφαιρικών ρύπων.

Αρχή λειτουργίας

1Η είσοδος καυσαερίων: Το αέριο που περιέχει σκόνη εισέρχεται στον πύργο απομάκρυνσης σκόνης από το κάτω μέρος ή τις πλευρές του σώματος του πύργου.

2. Πλύσιμο σκηνών με νερό/σπρέι

Το στρώμα της κουρτίνας νερού: Πολλαπλά στρώματα κουρτίνας νερού ή συσκευές ψεκασμού τοποθετούνται στον πύργο για να σχηματίσουν ένα φράγμα κουρτίνας νερού.

Ατμοποιημένες σταγόνες νερού: Οι ακροφύσια υψηλής πίεσης ατομικοποιούν το νερό σε λεπτές σταγόνες για να αυξήσουν την περιοχή επαφής με τη σκόνη.

3Μεταφορά μάζας αερίου-ρευστότητας: Τα σωματίδια σκόνης συγκρούονται και απορροφώνται με σταγονίδια νερού και αποθηκεύονται με την ροή του νερού.

4. Διαχωρισμός αερίου-ρευστικού: Το καθαρισμένο αέριο απελευθερώνεται μετά την απομάκρυνση της νερού που έχει εισχωρήσει από ένα αποσμητήριο (όπως ένας διαχωρισμός βαφλ, κυκλώνας).

5Αποχέτευση λυμάτων: Τα ακατέργαστα ύδατα που περιέχουν σκόνη ανακυκλώνονται μετά από ιζηματοποίηση ή αποχέονται μετά από επεξεργασία.

Εφαρμογές

Οι συλλέκτες σκόνης υδρατμών μας είναι ιδανικοί για διάφορες εφαρμογές στην παραγωγή λιπασμάτων, συμπεριλαμβανομένων:

Στρίψιμο και αλεύριση: Συλλογή σκόνης από διαδικασίες μείωσης μεγέθους.

Αναμίξη και ανάμειξη: Ελέγχος της σκόνης που παράγεται κατά τη διάρκεια της ανάμειξης των διαφόρων συστατικών λιπασμάτων.

Σκόρπιση: Απομάκρυνση της σκόνης από τη διαδικασία σκόρπισης.

Ξήρανση και ψύξη: Φιλτράρισμα σκόνης από στεγνωτήρια και ψυγεία.

Διαλογή και ταξινόμηση: Συλλογή σκόνης από τις εργασίες διαλογής.

Συσκευασία και σάκωση: Ελέγχος της σκόνης κατά τη διάρκεια της πλήρωσης και σφράγισης των σάκων λιπασμάτων.

Παράμετροι προϊόντος

| Σχήμα |

GF-20 |

GF-50 |

GF-100 |

Παραδείγματα εφαρμογής |

| Όγκος αέρα |

20,000 |

50,000 |

100,000 |

Μικρή γραμμή κόκκωσης/εργοστάσιο συσκευασίας |

| Δύναμη |

5.5kW |

11kW |

22kW |

Συστήματα κόκκων/θρυμματισμού με τύμπανο |

| Κατοικία |

2.5m2 |

4m2 |

6m2 |

Μεγάλο εργοστάσιο λιπασμάτων πλήρες σύστημα συλλογής σκόνης |

Ημερήσια συντήρηση

1- Επιθεώρηση του συστήματος κυκλοφορίας νερού

Παρακολούθηση της στάθμης του νερού: Βεβαιωθείτε ότι η στάθμη του νερού στην δεξαμενή νερού βρίσκεται εντός του οριζόμενου εύρους (η σκόνη λιπασμάτων απορροφά εύκολα το νερό, επομένως το νερό πρέπει να αναπληρώνεται εγκαίρως).

Παρακολούθηση της ποιότητας του νερού: Ελέγξτε την θολούρα του κυκλοφορούντος νερού.

Δοκιμή της τιμής pH: διατηρήστε το pH ≤ 6 (οξύ περιβάλλον) όταν χειρίζεστε αμμωνία και χρησιμοποιήστε χαρτί δοκιμής ή ηλεκτρονικό όργανο για καθημερινή δοκιμή.

2. Επιθεώρηση του συστήματος ψεκασμού

Διαπερατότητα του ακροφύλλου: Καθαρίστε χειροκίνητα τον φραγμένο ακροφύλλου (η κολλώδης σκόνη λιπασμάτων είναι εύκολο να φραγεί, συνιστάται η χρήση σπειροειδούς ακροφύλλου με διάφραξη ≤ 5 mm).

Σταθερότητα πίεσης νερού: Η ένδειξη του μετρητή πίεσης πρέπει να διατηρείται σε 0,3 ~ 0,6MPa. Εάν η διακύμανση είναι πολύ μεγάλη, ελέγξτε τη διαρροή της αντλίας νερού ή του αγωγού.

3Φαν και αγωγός

Ασυνήθιστη παρακολούθηση ήχου: Ασυνήθιστος θόρυβος από το ρουλεμάν μπορεί να υποδηλώνει ότι η σκόνη λιπασμάτων έχει εισέλθει στον ανεμιστήρα και πρέπει να σταματήσει για καθαρισμό.

Επιθεώρηση συσσώρευσης σκόνης στους αγωγούς: χτυπήστε τον οριζόντιο αγωγό και ο χαμηλωμένος ήχος δείχνει συσσώρευση σκόνης.και η πύλη καθαρισμού σκόνης πρέπει να ανοίξει (η συσσώρευση σκόνης λιπασμάτων είναι εύκολο να προκαλέσει πυρκαγιά)

Λεπτομέρειες για το προϊόν

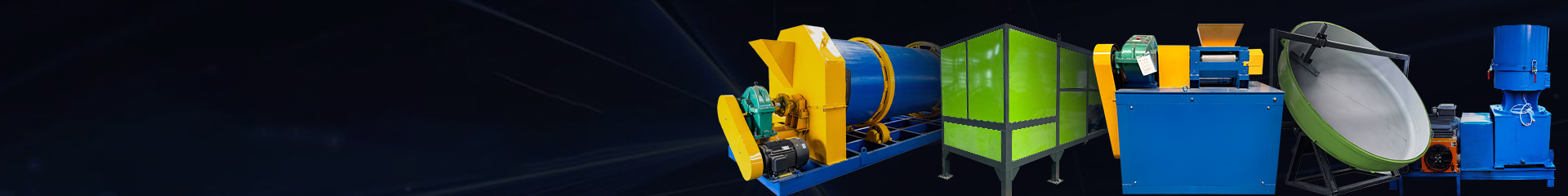

Περισσότερα μοντέλα εξοπλισμού απομάκρυνσης σκόνης

Σχετικά με εμάς

Ως προμηθευτής γεωργικών μηχανημάτων με περισσότερα από δέκα χρόνια εμπειρίας, η Gofine Machine παρέχει μια ποικιλία υπηρεσιών για να ανταποκριθεί στις ανάγκες των πελατών.

Παροχή διαφόρων τύπων γεωργικού εξοπλισμού, συμπεριλαμβανομένων των κοκκιστών οργανικών λιπασμάτων, των κοκκιστών σύνθετων λιπασμάτων, των κοκκιστών ανόργανων λιπασμάτων, των κοκκιστών υδατοδιαλυτών λιπασμάτων,Σκόρπες λιπασμάτων με ελεγχόμενη απελευθέρωση, μηχανές συλλογής λιπασμάτων, συντρίμμια, αναμεικτικά, στεγνωτήρια, μηχανές σχηματισμού κόκκων, μηχανές επικάλυψης, μηχανές διαλογής κόκκων, μηχανές συσκευασίας και ένα πλήρες σύνολο γραμμών παραγωγής λιπασμάτων.

Παρέχουμε επαγγελματική τεχνική συμβουλευτική και υποστήριξη για να βοηθήσουμε τους πελάτες να επιλέξουν τον σωστό εξοπλισμό και διαδικασίες και να βελτιστοποιήσουν τη διαδικασία παραγωγής.

- Εγκατάσταση και θέση σε λειτουργία

Παροχή υπηρεσιών εγκατάστασης και θέσης σε λειτουργία εξοπλισμού για τους πελάτες, ώστε να εξασφαλίζεται η κανονική λειτουργία του εξοπλισμού και να επιτυγχάνονται τα αναμενόμενα αποτελέσματα παραγωγής.

Παροχή εκπαίδευσης λειτουργίας για να βοηθήσει τους υπαλλήλους των πελατών να κυριαρχήσουν στις δεξιότητες χρήσης και συντήρησης του εξοπλισμού και να βελτιώσουν την αποδοτικότητα της παραγωγής.

Παροχή ολοκληρωμένης υπηρεσίας μετά την πώληση, συμπεριλαμβανομένης της τακτικής συντήρησης, της αντιμετώπισης προβλημάτων και της προμήθειας ανταλλακτικών, για να εξασφαλιστεί η μακροπρόθεσμη και σταθερή λειτουργία του εξοπλισμού.

Παρέχουμε εξατομικευμένο εξοπλισμό και λύσεις σχεδιασμού γραμμών παραγωγής με βάση τις ειδικές ανάγκες των πελατών μας για την κάλυψη των αναγκών παραγωγής λιπασμάτων διαφορετικών μεγεθών και τύπων.

Μέσω αυτών των υπηρεσιών, δεσμευόμαστε να παρέχουμε στους πελάτες μας εξοπλισμό λιπασμάτων υψηλής ποιότητας και ολοκληρωμένη υποστήριξη για να τους βοηθήσουμε να πετύχουν σε μια εξαιρετικά ανταγωνιστική αγορά.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!